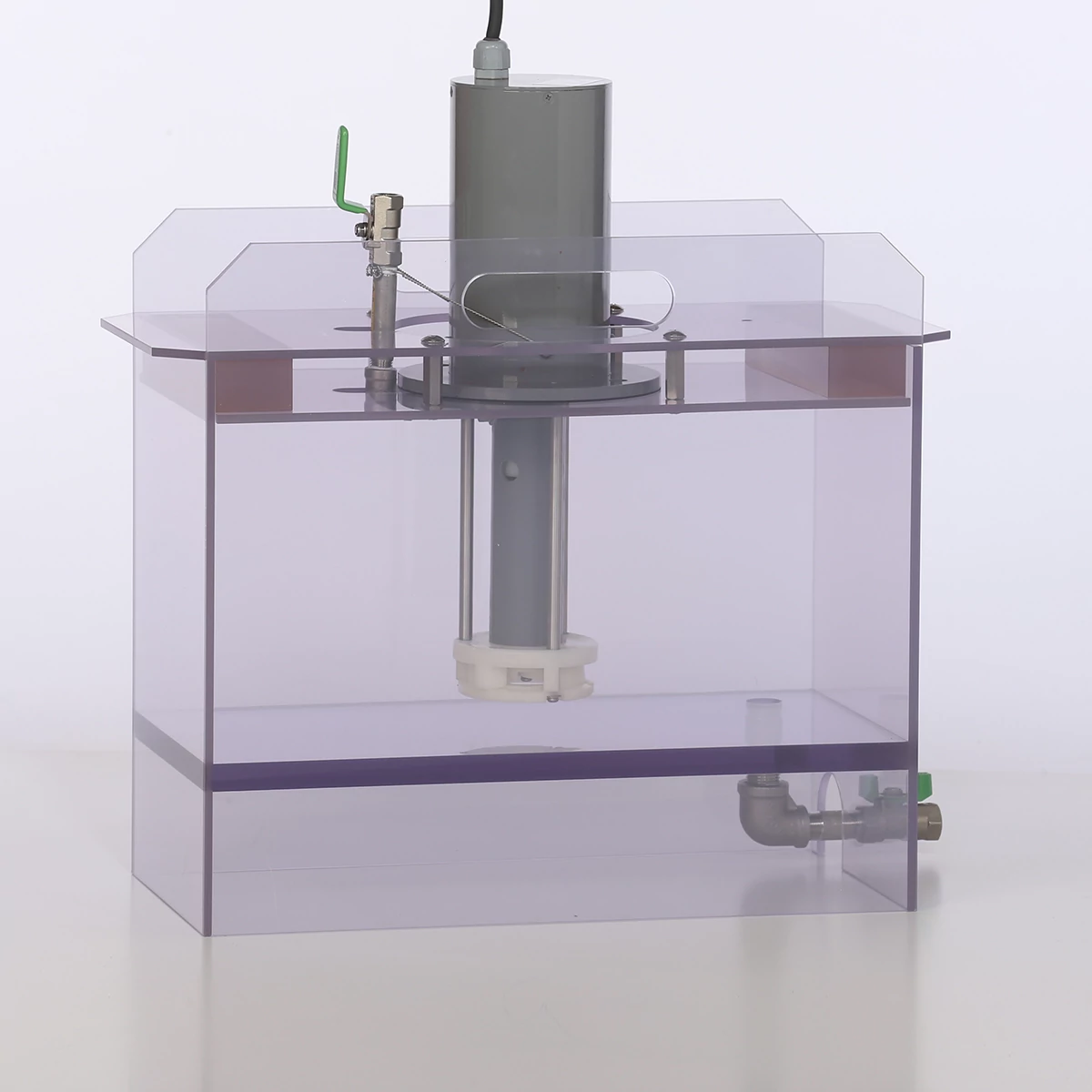

microStar Overview

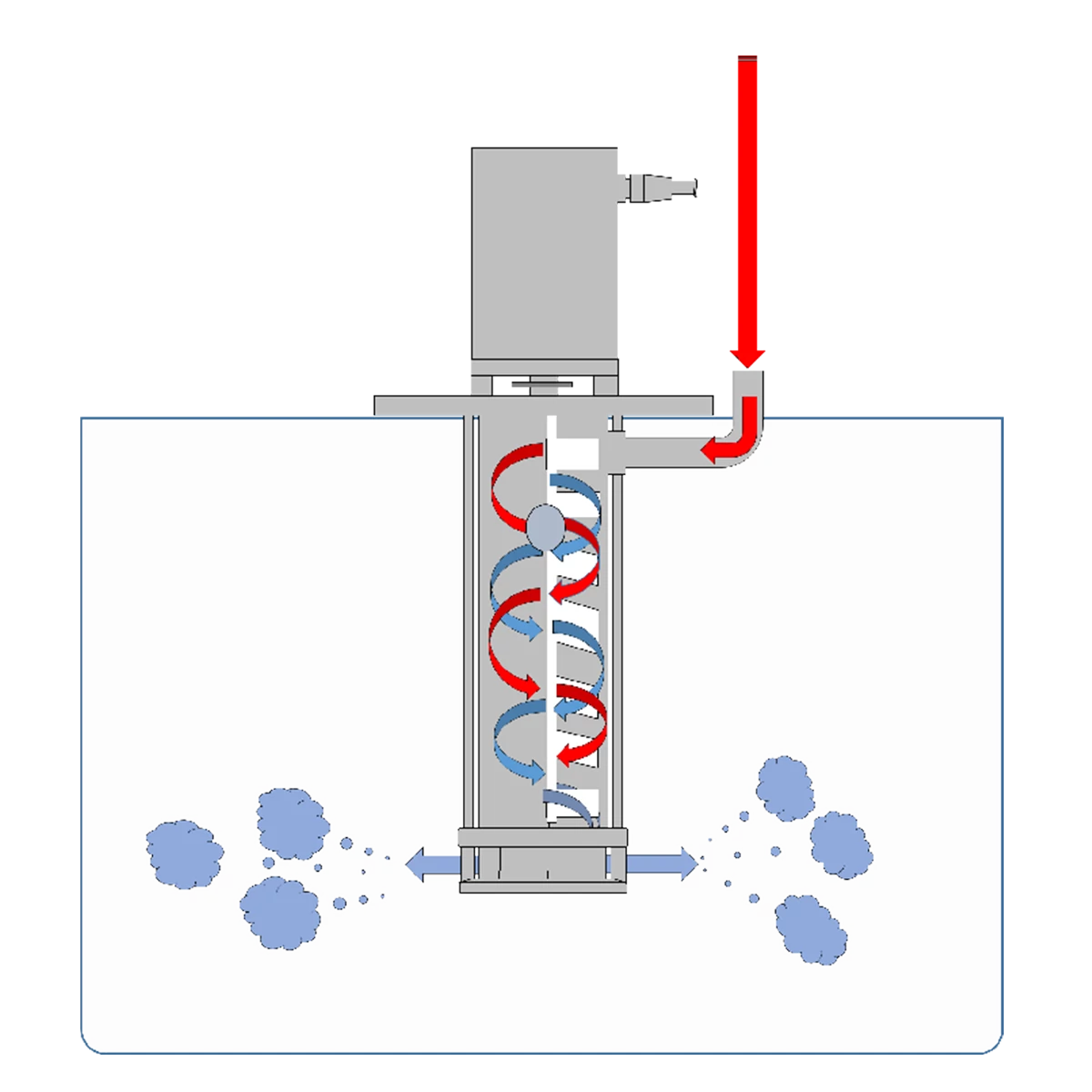

Hammer-rotation

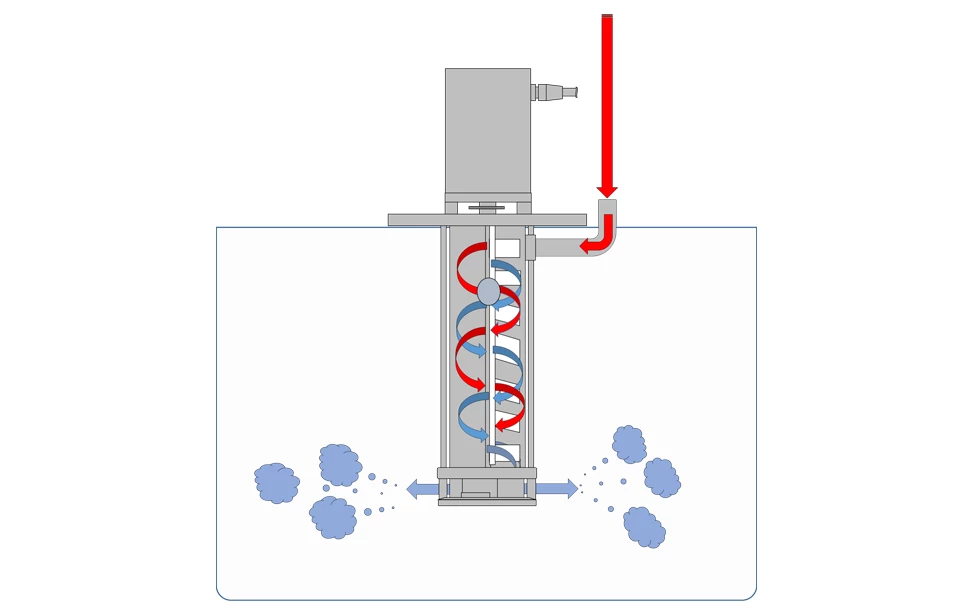

The patented hammermill rotation technology redefines nanobubble generation by eliminating the need for high-pressure pumps. A motor-driven shaft with precision-mounted hammers spins at 3,400 RPM inside a vertical tube, crushing injected gas into ultra-fine nanobubbles through mechanical shearing—not hydraulic force.

No turbulence

Water and gas enter from the top, while hammers at the shaft bottom dissolve and fragment gas molecules into high-concentration nanobubbles with zero turbulence. Because the system doesn't circulate large volumes of water or require pressurization, it delivers the lowest energy consumption per nanobubble in the industry. Think of projects like washing eggs to remove bacteria or bacteria bed filters, which should not be disturbed but require adequate amounts of gas.

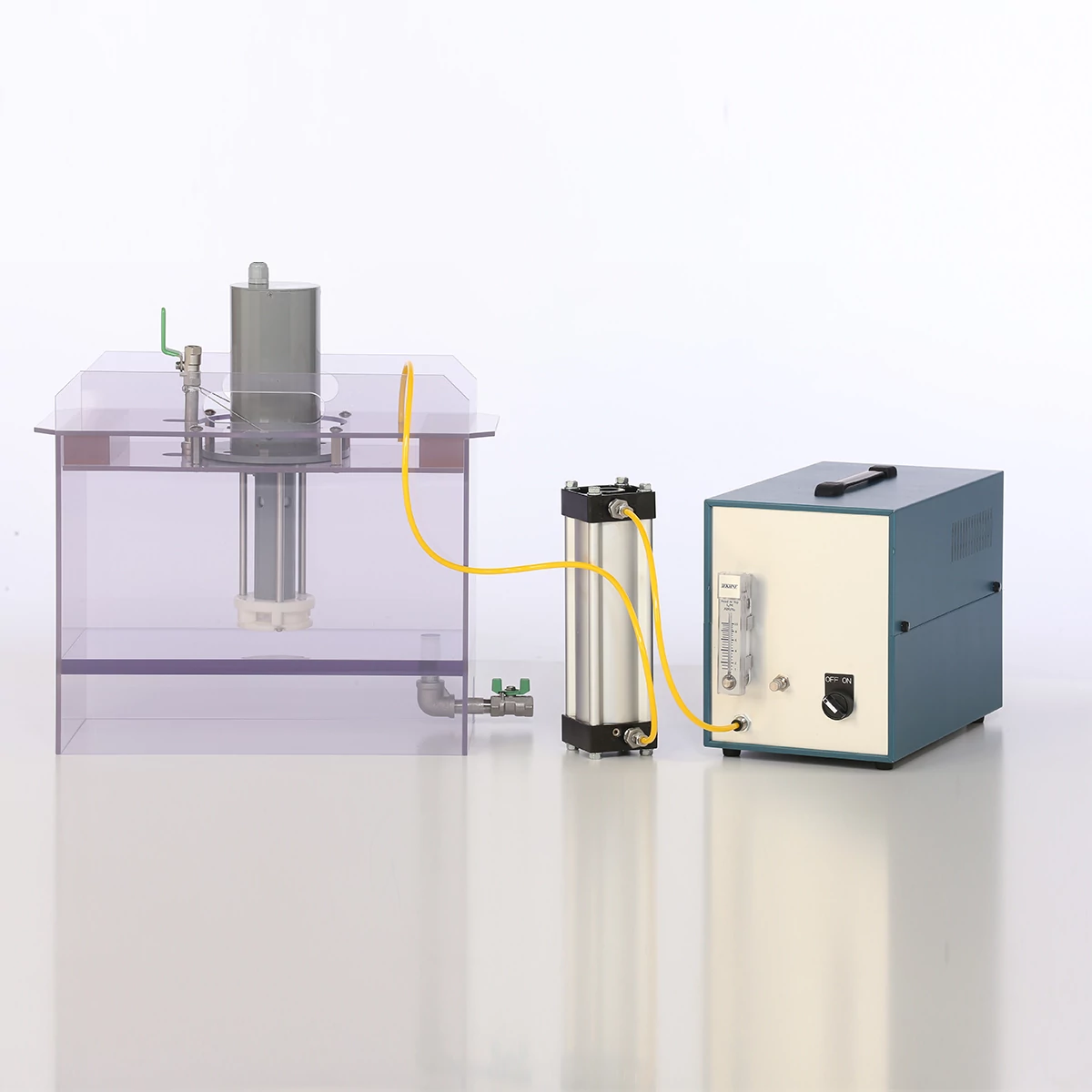

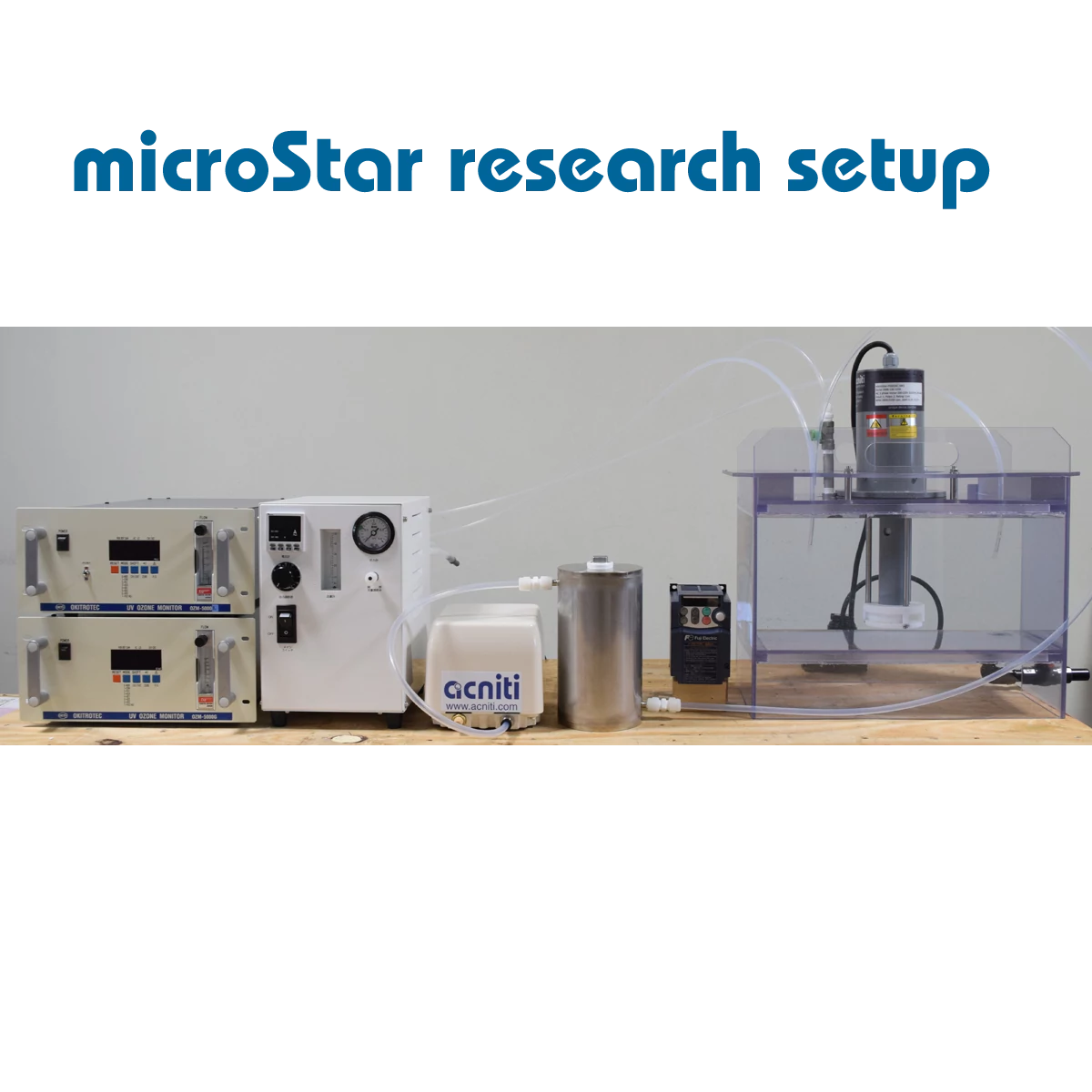

The microStar series leverages this hammermill design for ozone gas applications and harsh environments like seawater treatment, where corrosion resistance and energy efficiency are critical. Contact us for more details about this unique product. Currently, we have three sizes available. The smallest unit is ideally suited for research purposes; the two larger units can be used for production purposes.

Models & Specs

1. Nanobubble generator

| indication | name |

| FS | microStar |

2. Motor nominal input

| indication | motor nominal input |

| 30 | 30 Watt |

| 40 | 400 Watt |

| 15 | 150 Watt |

| 75 | 750 Watt |

3. Motor voltage

| indication | motor voltage |

| 1 | 100V~110V (AC models only) |

| 2 | 200V~220V (AC and DC models) |

4. Motor Power

| indication | power type |

| AC | AC-powered motor |

| DC | DC powered motor, high-spec, higher nanobubble concentration. |

5. microStar model

| indication | nozzle |

| "S" | short type |

| "L" | long type (not available now) |

6. Nanobubbles discharge

| indication | # directions |

| "W" | 2 directions |

| "S" | 1 direction |

7. microStar Throughput and Bubble Discharge Size

| indication | throughput / maximum micro bubble discharge size (reference value) |

| "1" | Standard / 1-30μm peak |

| "2" | Medium / 20-60μm peak |

| "3" | Large / mixing purpose only (no UFB generation) * special order model |

8. microStar special specs, special sign for customized model

| indication | specifications |

| "Sp" | special |

Ozone water concentration sensor

Discover the latest ozone water sensors from Acniti, designed for precise measurement of ozone levels in water ranging from 0 to 50mg/L. Equipped with advanced UV and polymeric membrane technology, these sensors are well-suited for research laboratories and industrial applications. The versatile options offer temperature compensation, analogue outputs, and portable models, helping you achieve reliable water quality analysis every time.

Ozone gas concentration sensor

Discover the latest ozone gas sensors from Acniti, designed for precise measurement of ozone levels in gas ranging from 0 to 50mg/L. Equipped with advanced UV and polymeric membrane technology, these sensors are well-suited for research laboratories and industrial applications. The versatile options offer temperature compensation, analogue outputs, and portable models, helping you achieve reliable gas quality analysis every time.

Ozone generators

Compact, air-cooled ozone generator producing 1, 12 or 21g/h. Metal-free gas path for clean ozone, ideal for water treatment and research. Heat stable.

Ozone destructor

Ozone destructor catalytic method to remove excess ozone. O3 destruction uses modular approach: Water trap, Heated chamber, Catalyst Sieve and Vacuum pomp.

Variable frequency drive 115V 1Φ100W

A variable frequency drive takes AC utility power and rectifies it to DC. The filter, usually a large capacitors where the DC power is stored and smoothed; and the inverter which takes that fixed DC voltage and converts it into adjustable frequency, adjustable voltage output for the control of an induction or synchronous motor.

Industrial Ozone Nanobubble Generator | MicroStar | Acniti

High-efficiency industrial ozone nanobubble generator using hammer-rotation technology. Achieve maximum ozone dissolution with zero turbulence and low energy. Ideal for food safety, water treatment, and research.